News

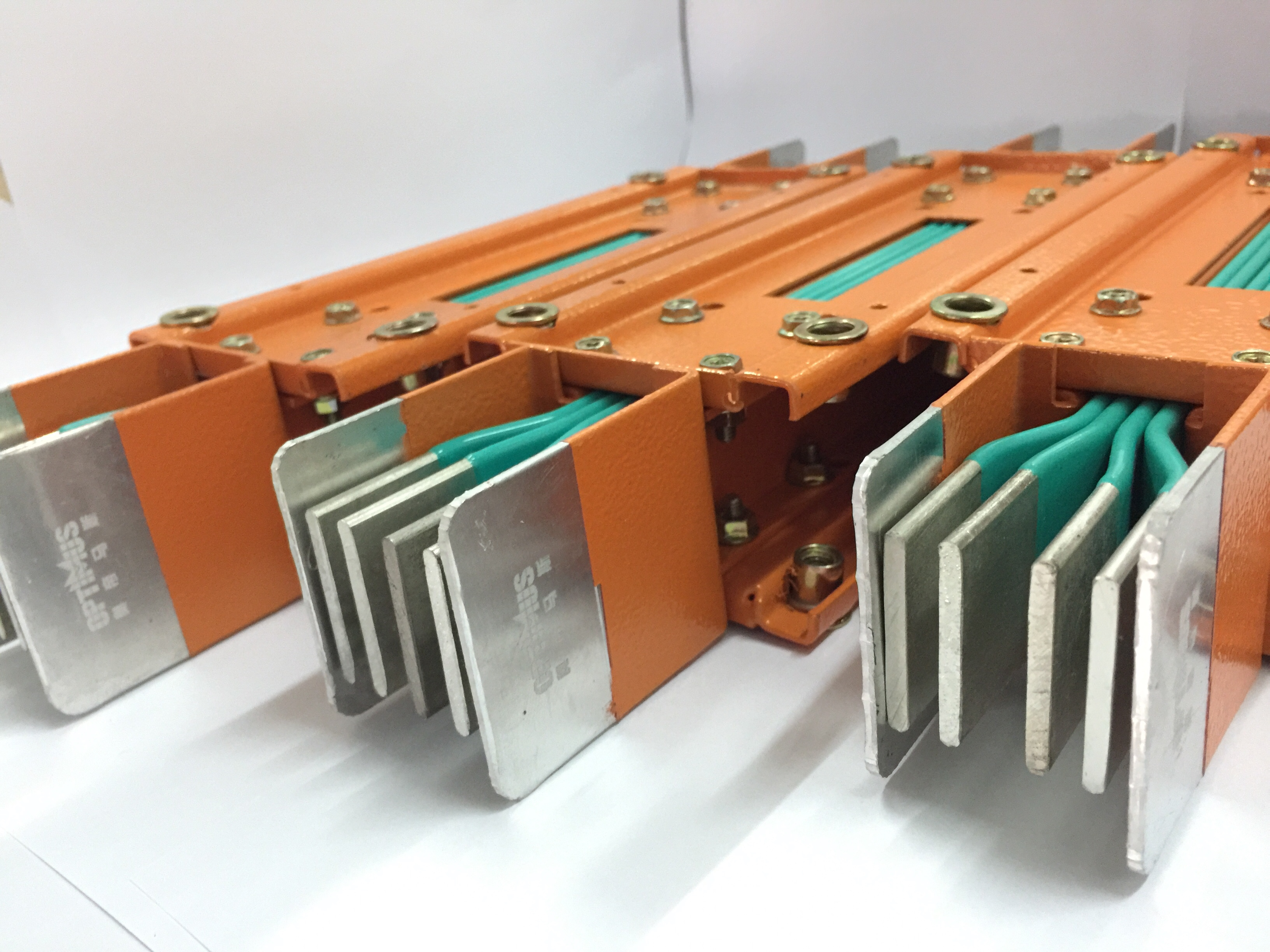

Advantages and disadvantages of Busduct and Cable

Reading volume:1623 Release time:2023-07-21 09:36:28

When using power cables for high current transmission and distribution in high-rise buildings and large factories, there are many intangible costs that need to be added. For example, during workshop transmission and distribution, each equipment and circuit needs to repeatedly lay control cables, and the safety control starting point of the cables can only be inside the distribution switchboard. If an emergency situation occurs and the power cannot be immediately cut off, it will cause huge safety risks and property losses, Especially in large-scale workshop projects, if power cables are used, they must be used together with high-strength bridges, high-density supports, and several fixed supports, greatly increasing the economic and maintenance costs of labor, auxiliary materials, and machinery, delaying the construction period, and reducing work efficiency.

The use of power cables in high-rise buildings and large plants is a serious waste, which increases the hidden trouble. For example, when 10000 meters and Busduct equivalent cross-section power cables are required for power supply in workshops, if the enclosed Busduct is selected, it is only 8000~9000 meters at most. Because of the large loss in cable budget, procurement, and construction, it is difficult to keep, store, and transport the cables, while the construction of Bus duct with equal cross-section is basically zero loss, Moreover, the technicians of the Busduct manufacturer will actively participate in and assist the site, optimize the site design, and provide full technical services free of charge, which will greatly reduce the customer’s use cost and save the time and effort.

From the comparison of Busduct and cable performance, the Busduct scheme is completely superior to the cable scheme. The cable has a long construction period, which is very difficult to maintain in the later stage, and it is difficult to check the abnormal conditions, which cannot be detected. The scheme of Busduct is fast in the construction phase, and the installation is simple, safe and reliable. In addition, centralized temperature monitoring can be achieved, which can effectively prevent abnormal equipment electricity usage. From the perspective of project investment and utilization, copper busduct is the most common, followed by cables, and aluminum busduct is the lowest. From the power loss curve of Busduct and cable after they are put into use, the cable loss is the largest in the cable operation process. Although the Busduct scheme is slightly larger in the initial stage of the project, after the later operation, the annual power loss of cable is much more than that of Busduct.

News

Honor

Contact Us

Contact:Mr.Jasper Liu

WhatsApp:+86 15205288168

Tel:+86-511-88136688

Email:salesmegachina@optimus-busduct.com(Click on email to inquire about quotation)

Address:No. 36 Ganglong Road, Economic development zone,Yangzhong,JiangSu province,China