News

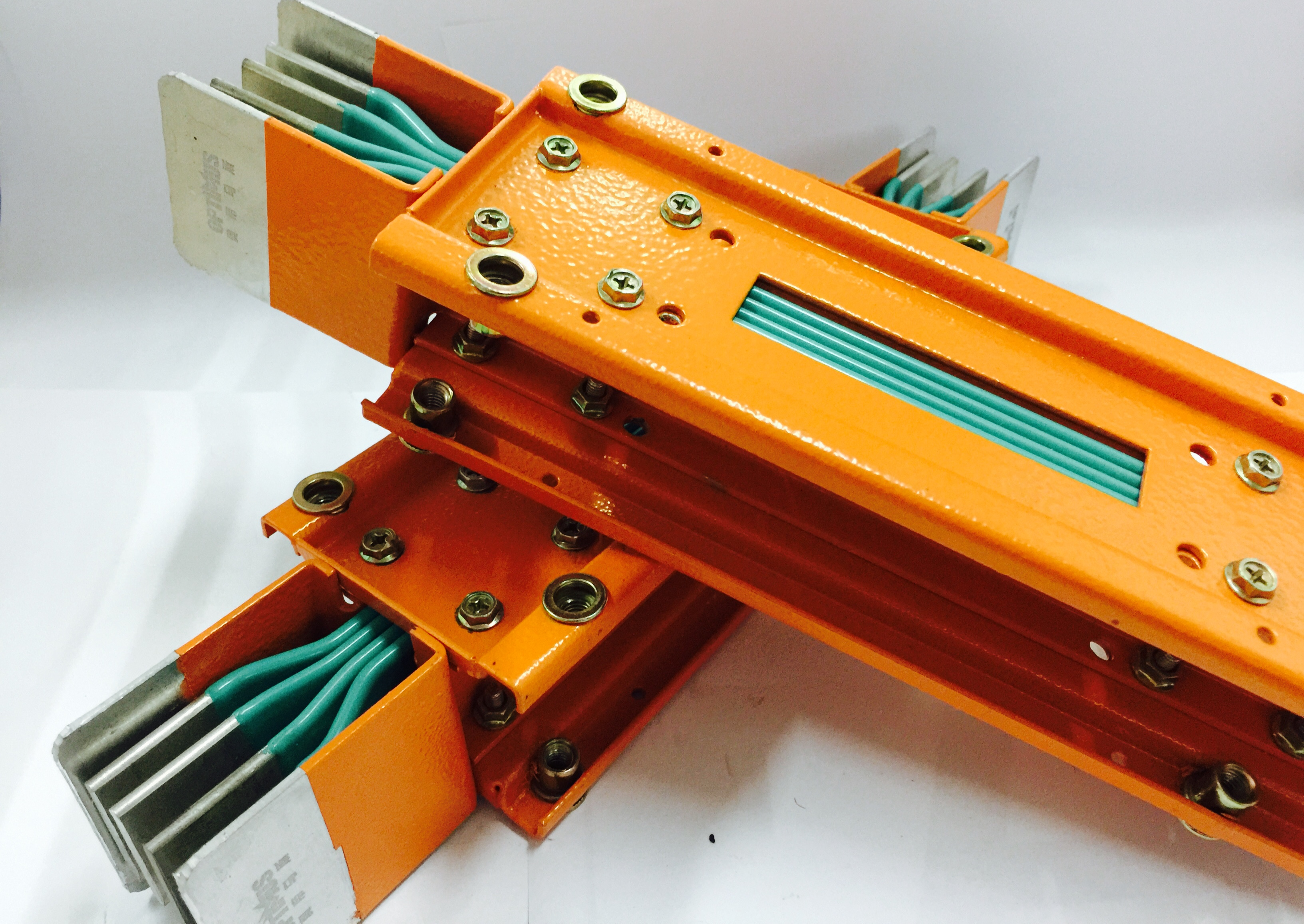

Installation preparation and steps of busbar

Reading volume:463 Release time:2023-06-09 16:28:39

I.Installation personnel

The installation, operation and maintenance of busway shall be carried out by professionals. The busway installation personnel shall have the following abilities:

1. Be familiar with busway structure, installation, construction and operation;

2. Shall undergo training on power transmission and testing of electrical equipment systems;

3. Have a high level of safety awareness and complete safety protection (such as safety helmets, work clothes, safety gloves, etc.)

II.Installation and measuring equipment of busway

1. Hoisting equipment: scaffolding, miter ladder, manual hoist;

2. On site production equipment: temporary power supply, impact drill, cutting machine, welding machine, etc;

3. Locking equipment: screwdriver, socket, torque wrench, ordinary wrench;

4. Testing equipment: level gauge, tape measure, suspension, 1000V megohmmeter;

All installation steps must be completed without electrification, and any electrification installation behavior is prohibited. Any live installation behavior should be stopped. The following are the installation steps of busway:

1. According to the final design direction of busway, confirm whether the obstacles and reserved positions on the direction have changed;

2. Fabrication and installation of busway support on site;

3. Conduct insulation testing before installation, and the insulation of a single busway should be greater than 20 megaohms;

4. Hoist and connect the busway according to the busway routing diagram and installation number. Retest the insulation of the installed busway before installation the next day. At the end of installation every day, the end of busway shall be protected;

5. Connect busway with power distribution equipment (switchgear, transformer, etc.);

6. Install plug-in boxes and other devices;

7. Perform insulation test on busway system, and power can be transmitted only when it is greater than 0.5 megohm;

8. Check the phase sequence before power transmission;

9. Power transmission.

Mega Technology has strong R&D resources in the busbar industry, focusing on epoxy resin vulcanization insulation technology, with excellent quality and satisfactory service. Mega Technology (Zhenjiang) Co., Ltd. has obtained CQC certification for its entire series of OPTIMUS busbar products, as well as international authoritative Kema keur certification and UL certification. We have completed many projects in both domestic and international markets, and are continuously conducting product research and development, adopting advanced thermodynamic applications and manufacturing methods to provide high-performance and high-quality products to our customers.

PREV:没有了

NEXT:Function of Busway

News

Honor

Contact Us

Contact:Mr.Jasper Liu

WhatsApp:+86 15205288168

Tel:+86-511-88136688

Email:salesmegachina@optimus-busduct.com(Click on email to inquire about quotation)

Address:No. 36 Ganglong Road, Economic development zone,Yangzhong,JiangSu province,China