News

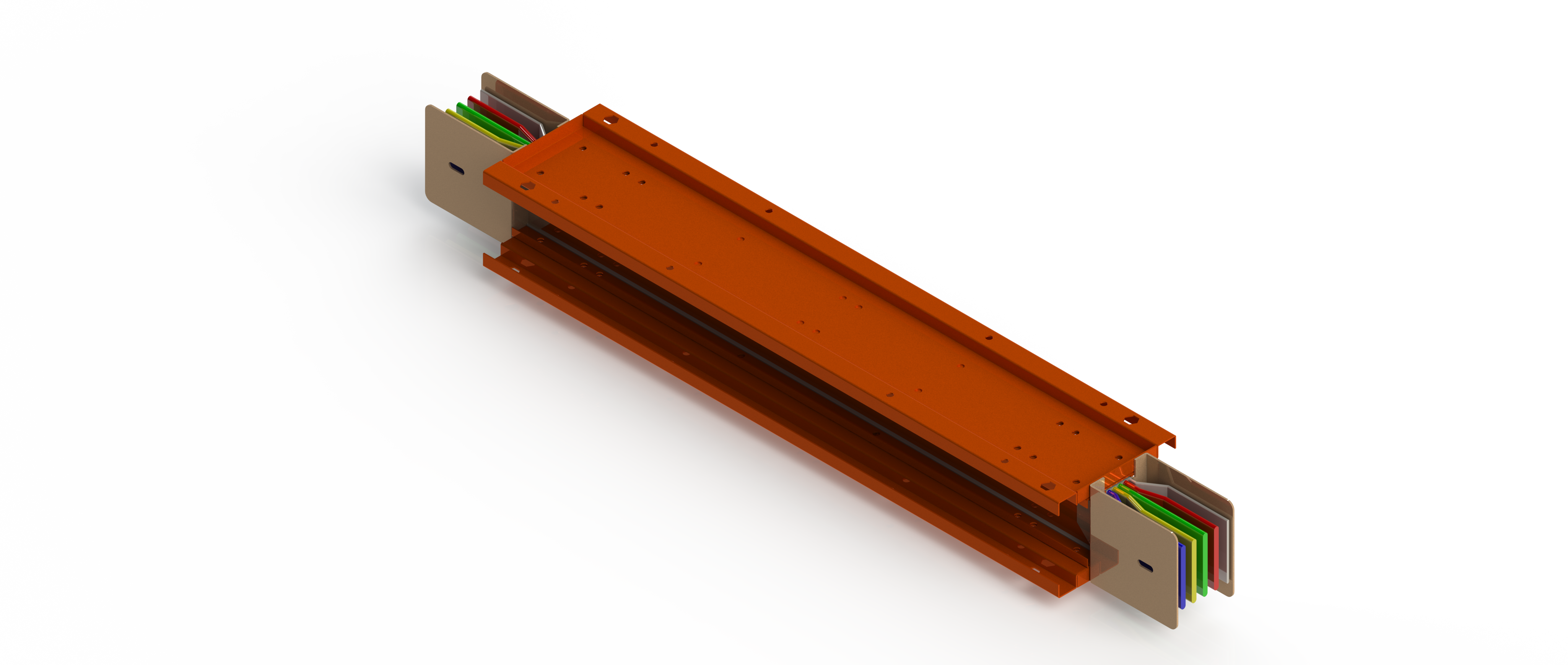

Precautions for using Busduct

Reading volume:582 Release time:2023-09-25 15:24:35

Before power transmission, it must be confirmed that the insulation resistance of the entire busduct system must not be lower than 0.25M Ω. Before power transmission, check the tightness of the connectors of the entire busduct system to prevent leakage or other looseness. Ensure that all tapping devices are in a disconnected state. Check if the phase sequence of the busduct is consistent with that of the incoming and outgoing line system. Only qualified professional electrical installation personnel can power the equipment, and non professional personnel must evacuate the site. When starting power transmission, the busduct cannot carry a load.

Within 6 months after the installation and use of the busduct, check the joint connection bolts (65N • M~70 N • M) and the fixing bracket bolts for looseness. After 1 year, conduct a comprehensive inspection, and the rest must be thoroughly inspected internally and externally every 3 years.

Check that the total load current does not exceed the main busduct slot current or design current, and check the temperature of the operating site.

Before maintenance of the busduct, it is necessary to conduct a power outage check on the busduct system! Completely cut off all power to the busduct! And use a multimeter to measure the voltage of the conductive body and confirm that the busduct system is not live before routine maintenance. Prevent serious accidents where high voltage can cause physical injury or even death to operators!

During the maintenance period, a soft brush, vacuum cleaner, or cotton cloth can be used to clean the dust on the busduct. During the operation of the busduct, it is necessary to continuously check the surrounding area of the entire system for leaks, water spray, potential sources of moisture, heavy objects that pose a threat to the system, and heat sources that affect the temperature rise of the busduct system. Check for foreign objects entering the interior of the busduct.

Check the components of the busduct system for defects, rust, and proper elasticity of the support spring. If any problems are found, replace them immediately. During long-term operation of the busduct, the temperature rise of the joint should be regularly tested once a year. The temperature rise of the joint should not exceed 70K according to the GB7251 standard as qualified.

Check for aging of insulation materials and melting deformation of conductive parts. If any phase to phase grounding or insulation breakdown is found, it should be removed in sections and inspected with a withstand voltage tester to identify the fault, or the busduct should be replaced, or insulation wrapping treatment should be carried out again. Check if the pins of the plug-in box of the busduct system have good contact with the busbar. Before re energizing the busduct system, the insulation resistance should be checked and recorded for archiving. Ensure the original protection level requirements of the busduct system after maintenance.

News

Honor

Contact Us

Contact:Mr.Jasper Liu

WhatsApp:+86 15205288168

Tel:+86-511-88136688

Email:salesmegachina@optimus-busduct.com(Click on email to inquire about quotation)

Address:No. 36 Ganglong Road, Economic development zone,Yangzhong,JiangSu province,China